Maximizing Efficiency and Minimizing Maintenance Costs with Diesel Generators

Introduction

In today's fast-paced world, uninterrupted power supply is crucial for various industries, businesses, and households. Diesel generators have long been a reliable and efficient source of power backup, offering consistent performance and durability. One of the key advantages of diesel generators is their low maintenance requirements compared to other types of generators. In this article, we will explore the reasons behind the low maintenance needs of diesel generators and how users can maximize efficiency while minimizing maintenance costs.

Understanding Diesel Generators

Diesel generators are widely used for standby power applications, emergency backup power, and prime power generation. These generators are powered by diesel engines, which convert diesel fuel into mechanical energy that drives an alternator to produce electricity. Diesel generators come in various sizes and power capacities to meet the diverse needs of users, from small residential units to large industrial installations.

Key Features of Diesel Generators

Diesel generators offer several key features that make them a popular choice for power backup solutions. Some of the key features of diesel generators include:

1. Durability: Diesel generators are known for their robust construction and durability, making them suitable for continuous operation in harsh environments.

2. Fuel Efficiency: Diesel engines are more fuel-efficient compared to gasoline engines, providing cost savings over the long term.

3. Low Maintenance: Diesel generators require minimal maintenance compared to other types of generators, reducing downtime and maintenance costs.

4. Longevity: Diesel generators have a longer lifespan compared to gasoline generators, providing reliable power backup for many years.

5. High Power Output: Diesel generators can deliver high power output, making them suitable for demanding applications where a continuous power supply is essential.

Reasons for Low Maintenance Needs of Diesel Generators

There are several reasons why diesel generators have low maintenance requirements compared to other types of generators. Understanding these reasons can help users maximize the efficiency and longevity of their diesel generators while minimizing maintenance costs. Some of the key reasons for the low maintenance needs of diesel generators include:

1. Simple Design: Diesel generators have a simple design with fewer moving parts, reducing the chances of wear and tear and the need for frequent maintenance.

2. Robust Construction: Diesel generators are built to withstand heavy-duty operation, with durable components that can withstand high temperatures and challenging conditions.

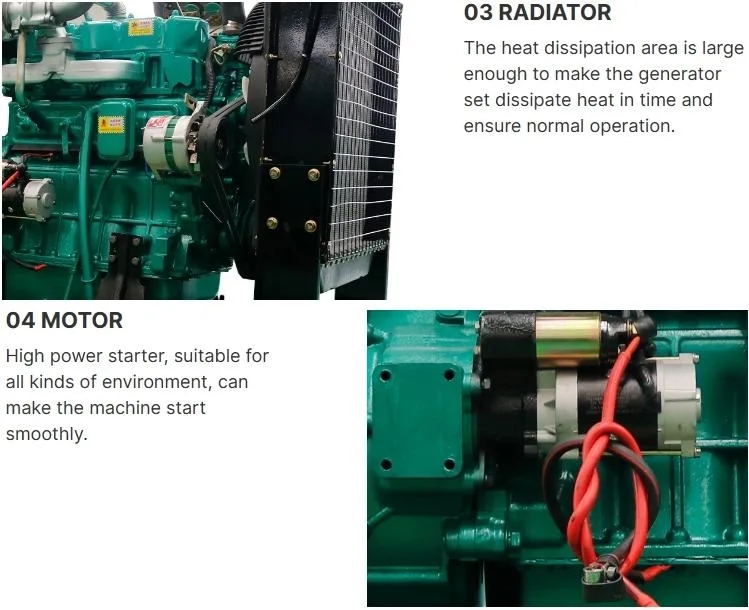

3. Efficient Cooling System: Diesel generators are equipped with efficient cooling systems that help regulate engine temperature and prevent overheating, reducing the risk of mechanical failures.

4. High-Quality Components: Diesel generators use high-quality components and materials that are designed for durability and reliability, minimizing the need for frequent repairs and replacements.

5. Regular Maintenance: While diesel generators have low maintenance needs, regular maintenance is still essential to ensure optimal performance and longevity. Simple maintenance tasks such as oil changes, filter replacements, and fuel system checks can help prevent issues and extend the lifespan of the generator.

Maximizing Efficiency and Minimizing Maintenance Costs

To maximize the efficiency and minimize maintenance costs of diesel generators, users can follow these best practices:

1. Regular Inspection and Maintenance: Conduct regular inspections of the diesel generator to check for any signs of wear or damage. Perform 600kw diesel generator for remote development projects as oil changes, filter replacements, and fuel system checks as recommended by the manufacturer.

2. Proper Fuel Storage: Ensure that diesel fuel is stored in a clean and dry environment to prevent contamination and degradation. Use high-quality fuel that meets the specifications recommended by the generator manufacturer.

3. Load Testing: Periodically test the diesel generator under load conditions to ensure that it can handle the required power output. This helps identify any potential issues and ensures the generator is ready for use in case of a power outage.

4. Professional Servicing: Engage qualified technicians to perform regular servicing and maintenance of the diesel generator. Professional servicing can help identify and address any underlying issues before they escalate into major problems.

5. Keep a Maintenance Log: Maintain a detailed maintenance log that records all maintenance activities, inspections, and repairs performed on the diesel generator. This log can help track the generator's performance over time and schedule future maintenance tasks.

Conclusion

Diesel generators offer a reliable and efficient power backup solution with low maintenance requirements compared to other types of generators. By understanding the reasons behind the low maintenance needs of diesel generators and following best practices for maintenance and efficiency, users can maximize the performance and longevity of their generators while minimizing maintenance costs. With proper care and regular maintenance, diesel generators can provide uninterrupted power supply for many years, ensuring peace of mind for businesses, industries, and households alike.